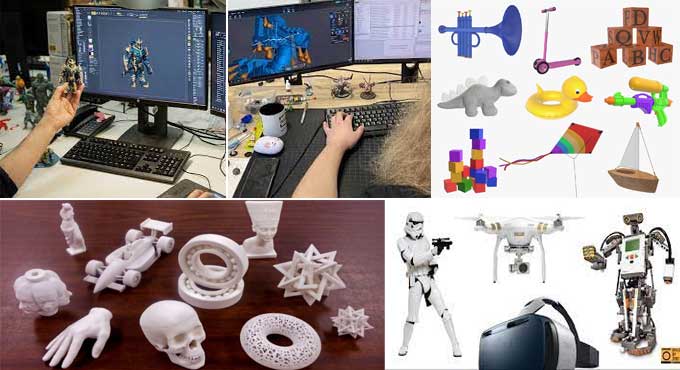

8 ways to use 3D models and prototypes in Toy Manufacturing

Besides accelerating development, 3D modeling also improves precision when operating machines, encourages the development of new toys, and reduces production costs. The following are some of the several ways that 3D models and prototypes aid in the creation of toys.

Cost Effectiveness and Sale Economics

Creating molds for multiple iterations of designs can be significantly reduced with 3D modeling from the perspective of manufacturers. By fabricating 3D prototypes of toys, manufacturers are able to estimate the costs associated with the processes and materials involved in toy development.

Multiple tests can yield valuable data that can be used to improve the design of the product significantly. As a result, the use of 3D modeling enhances cost-effectiveness throughout mass production, ensuring efficiency and precision in the finished product.

Bulk Customization

It is not practical to produce more personalized toys using traditional manufacturing methods such as casting or injection due to the high amount of time and tooling costs involved. Typically low manufacturing costs do not justify the time and cost of developing customized toys in this particular scenario.

The disadvantages of tooling fabrication can also be alleviated by using 3D modeling. The use of 3D printing molds also allows toy manufacturers to create more intricate and personalized mold designs at a lower cost faster.

Easy Process of 3D Toy Prototyping

Before introducing a new product, a concept or idea must be transformed into a physical product. This process relies heavily on 3D toy prototyping, which allows toy designers to assess a toy's appearance and functionality.

For prototyping, 3D printing is widely recognized as the best technology. It provides flexible and cost effective ways to produce visual and functional prototypes. To evaluate and test their toys with potential distributors and end users, toy manufacturers use 3D printing.

Data Management Efficiency

Data management is a challenge for 3D modeling experts and manufacturers, especially when dealing with multiple product evolutions and revisions. By streamlining the process of managing design data, switching from 2D to 3D modeling can significantly improve productivity. By using 3D modeling software, you can track design information more efficiently and update components automatically.

With 3D modeling software, every component in the design can be updated automatically. In addition, 3D modeling ensures team members are aligned and working with consistent and current information through standardizing drafting procedures. Through 3D modeling, collaboration within the design process is enhanced and errors and miscommunications are reduced.

Safety

It is important to pursue new creative and immersive play experiences, but not at the cost of physical safety. Negligent safety can undermine the product development process as well as end users. It is crucial for toy manufacturers to follow existing consumer safety specifications for toy safety in order to reduce this risk. Besides outlining design considerations and material requirements, these specifications define a comprehensive set of technical standards to ensure toy safety.

Toys that promote the well being of children should feature unified standards and testing protocols to facilitate the production of safer products globally. Using traditional prototyping methods can make it difficult to adopt safety standards. Engineers who design 3D prototypes are more efficient since their designs can be checked for safety and functionality and easily modified as needed.

A controlled test environment can also be used to evaluate 3D printed toys for various factors, including their durability, safety, and functionality. By using 3D models and prototypes, it is also convenient to present toy samples to prospective buyers and distributors and get feedback from them. Following these prototypes and tests, the final product can be developed based on the insights gained from these prototypes and tests. This will ensure that safety standards and consumer expectations are met.

Using 3D printing, toy manufacturers can create multiple designs, each with enhanced features, materials, and ergonomics, as the revision process can be streamlined. In the same way as other industries, toy makers can optimize their toys and achieve market success by implementing the Continuous Improvement Process.

In the toy development process, 3D models and prototypes enable manufacturers and designers to develop toys that reflect their creative vision while operating with greater confidence in the final product's quality and safety. By using 3D technology, toys may be designed in a way that is even more innovative and of higher quality.

New Toys Development

The advent of creative toys is welcomed by the toy business, and 3D modeling is proving to be a useful tool in this field. The purpose of educational toys is to assist kids improve their fundamental knowledge of subjects like science, technology, engineering, and math. One noteworthy instance is the development of kid friendly 3D printers that enable kids to design, print, and produce toys.

Through this practical learning opportunity, kids may participate in technology and engineering ideas while also developing their creativity and problem-solving abilities. Integrating 3D modeling and printing technology offers toy manufacturers a chance to broaden their product lineup and support the future generation's educational advancement.

To learn more, watch the following video tutorial.

Video Source: SMP Films

Better Customer Relationship

With 3D modeling, toy developers can build stronger relationships with their customers and engage them with their products. Toy companies can invite firms to submit 3D designs, and the most exceptional can be selected for 3D printing as limited editions. Toy companies benefit from this collaborative approach not only by tapping into the creativity of their customers, but by also cultivating a sense of community and empowerment among the communities of toy enthusiasts.

Better Communications

It is faster and more effective to evaluate internal designs using a 3D model rather than a 2D image. Through 3D modeling, internal teams, suppliers, and consumers can communicate better, reducing market time. Furthermore, 3D models allow designers to make informed decisions and refine designs with greater precision and confidence by allowing interactive exploration and modification.